Companies that specialize in CNC machined plastic can produce PEEK plastics of larger sizes and in more quantities.

#Peek material full form how to#

ARKPEEK will know exactly how to transform your exact PEEK material into the durable part that you need. If you know that you are in need of processed PEEK plastic, consider reaching out to PEEK plastic manufacturers. CNC plastic machining is ideal for parts larger than 600mm. 1431 221 Annas o edica and eat ciences esearc riginal Articleeview Article Abstract Background: Various studies reveal that the elastic modulus of the Polyether Ether Ketone (PEEK) material is very close to dentin tissue thus, less stress formation occurs in the tooth, and post-core restoration compared to other post systems was observed. No molds are needed in CNC machining, therefore reducing startup time and costs. The automated CNC machine is controlled by a computer that determines the path of the machine cutter according to the 3D file created. PEEK CNC machining is popular because it is the most efficient and economical option for the rapid production of prototypes and plastic models. The medical PEEK used in this study was obtained in two ways: PEEK-OPTIMA LT1, developed at a stretched shaft diameter of 25 mm and an experimental filament diameter of 1.75 mm, according to the described procedure 44,45,46,47. CNC machined plastic is made by machining in the mass of a plastic block by milling machines with 3 axes with digital control.

#Peek material full form manual#

CNC machines process materials by following a coded programmed instruction instead of a manual operator. CNC, or computer numerical control, is the automated control of machining tools by a computer. For the best PEEK injection moulding performance, additives found in PEI plastic can be pre-compounded into PEEK plastic to make it ideal for injection molding.Ī PEEK plastic CNC machine is the second most common type of PEEK processing. To keep your PEEK plastic clean, keep any contaminants away during PEEK processing. If your PEEK plastic is in pellet form, you can dry them on trays that circulate in an oven for 2-3 hours.

For the best PEEK injection molding process, it is crucial to keep the PEEK plastic clean and dry. Once the plastic cools and hardens, it's transformed into a strong and durable plastic part for your project or industry.įor PEEK injection molding, processing temperatures ideally need to be somewhere between 662☏-752☏. The plastic is melted into the injection molding machine and then into your customized mold. PEEK plastic is processed through an injection molding machine and unique molds to form raw plastic materials into the parts you need.

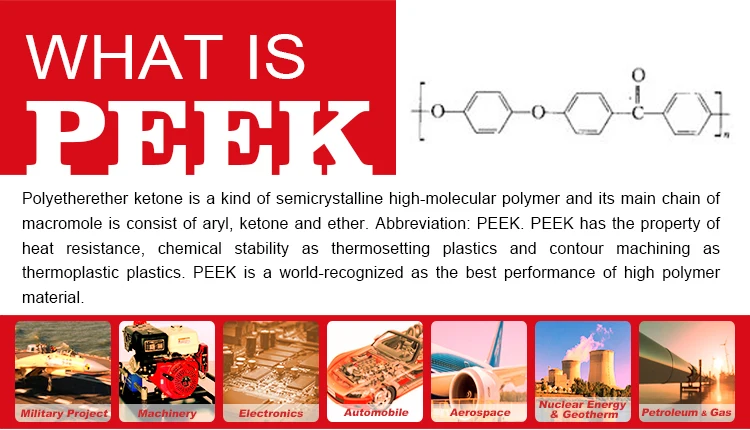

Stable at elevated temperatures up to 170☌/338☏ MATERIAL SPECIFICATIONS & MECHANICAL PROPERTIES OF PEEK Read on to learn about the two different types of PEEK processing. PEEK plastics can be manufactured in two different ways: PEEK injection molding or PEEK machining. They are specially engineered plastics that are designed for very specific applications. PEEK plastics are not designed for every day or generic use. Many parts made from PEEK are found in environments where temperature or chemical exposure poses a problem. PEEK plastic is available in blocks, rods, sheets, pipes, powders, or pellets. PEEK plastic, also known as polyether ether ketone is a high-performance thermoplastic polymer. In today's advanced world, engineered plastics such as PEEK are sought after to replace metals and increase the performance of certain parts. Plastic has evolved tremendously since its first uses in society, and every day, new uses and modifications are discovered. Read on to learn about the two different types of PEEK processing.HOW TO PROCESS PEEK MATERIAL | PEEK INJECTION MOLDING VS PEEK MACHINING Vision Miner company specializes in PEEK and PEI, but let’s look at the differences between each. They are specially engineered plastics that are designed for very specific applications. Filament materials like PEEK, PEI, PAEK, and PEK can be confusing.

0 kommentar(er)

0 kommentar(er)